In recent years, the development of new charcoal making machine industry around the world has become more and more rapid, and the development tendency towards the charcoal industry in the international market is very promising at this point in time. In spite of the fact that the rate of development of new charcoal machines has slowed down over the course of the past two years, according to the statistics, the industry of new charcoal making machines has also ushered in a good development opportunity in the rapid development of the world economy.

The first machine ever developed for the production of charcoal, which relied primarily on wood chips as its source of raw material. The first thing that happens during the manufacturing process is that the machine uses high heat and pressure to start the process of chipping wood, which is the primary step. After that, the wood chips are taken to the carbonization furnace where they will go through the process of being carbonized. In order to fulfill the requirements for inclusion in the category of products that are less harmful to the natural environment, the production process does not call for the use of any additives at any point. As a replacement for traditional charcoal (traditional charcoal: continuous carbonization furnace is a kind of industry that depletes resources by utilizing trees as raw materials), Continuous carbonization furnace manufacturer has the advantages of a long burning time, a high calorific value, the absence of a large amount of smoke, and the protection of the environment. Traditional charcoal: continuous carbonization furnace supplier is an industry that depletes resources by utilizing trees as raw materials.

In its most fundamental form, charcoal can be understood as follows: its primary component is carbon, it has a very low ash content, and its calorific value ranges from approximately 27.21 to 33.49 MJ/kg.

There are also a few other elements, such as hydrogen, oxygen, and nitrogen, in addition to these. The information that is included in the element is unrelated to the species of tree in any way, shape, or form. The highest temperature at which carbonization can take place is by far the most important factor to consider in making this determination.

Charcoal is a substance that is hydrophobic, and it has an ash content that is lower than 6% and a pore volume that is higher than 7% of the total amount of charcoal. The calorific value is generally determined to be somewhere in the neighborhood of 8,000 kcal/kg, and the capacity of charcoal to reduce is higher than that of coke. The manner in which charcoal was carbonized has a direct bearing on the conditions that determine its calorific value. When the tar-like substance that was previously present in the pores of the charcoal is removed, the charcoal reveals that it possesses a high surface area and excellent adsorption capabilities due to the large number of microporous and transition orifices that it possesses. This is because it possesses a large number of microporous and transition orifices. Oxygen burns completely to produce carbon dioxide, but carbon dioxide does not burn completely, which results in the production of carbon monoxide, which is a poisonous gas. Oxygen is necessary for the production of carbon dioxide. For the purpose of determining the number of calories that are offered by charcoal, a tool known as a microcomputer calorimeter is utilized.

Charcoal is able to fulfill the requirements of the modern living environment because it does not produce smoke, has no flavor, and does not contain any toxic chemicals. In addition, charcoal possesses a number of other desirable qualities. Charcoal's versatility has led to its widespread adoption in a variety of industries, including home heating and the barbecue industry, both of which contribute to its current level of popularity.

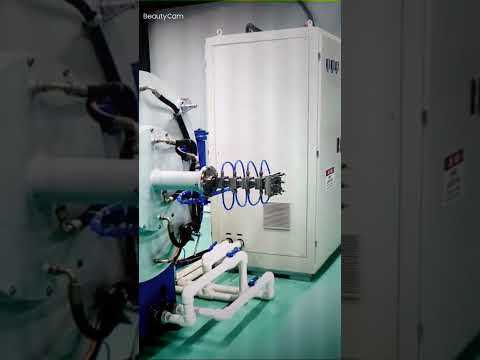

The initial phase of the manufacturing procedure for a machine that produces charcoal

Every industrial company has carried out their policies in a consistent manner in order to aim for environmentally friendly and sustainable growth of their business. This is because the implementation of the initiative that places an emphasis on environmentally friendly production is proceeding smoothly. The production of charcoal in a manner that is both clean and kind to the environment has made a sizeable contribution to the program for environmentally responsible manufacturing.

The creation of charcoal making machines with the capacity to generate high-quality charcoal has been the primary focus of research and development efforts. Products consisting of charcoal can be produced by converting materials that contain significant amounts of biomass using the machine that is used to make charcoal. Have you ever given any thought to the process that goes into making charcoal with a machine specifically designed for that purpose? If the operators of the charcoal making machine are the only ones who understand and comprehend the working theory of the process flow, then the improved charcoal making effect that exceeds the quality of the average charcoals cannot be obtained.

The production of charcoal can be broken down into its four primary components, which are the preparation of the raw materials, the pressing of raw material blocks, the carbonization of sawdust blocks, and the treatment of soot, in addition to any additional subsidiary processes that may be required. The making of charcoal by means of a machine entails the utilization of a number of distinct manufacturing procedures, all of which must be completed in order to create the finished product. When each of the procedures has been carried out to its conclusion, the initial raw material will have been converted into charcoal.

The steps of crushing, screening, drying, and transporting the raw materials are included in the process of preparing the materials;

Extrusion briquette production, sawdust block cutting, and sawdust block collection are all steps in the process of making briquettes from raw materials.

There are a number of steps involved in the process of sawdust block carbonization, including sawdust block transportation, sawdust block stacking, sawdust block carbonization, and carbonization.

The process of treating dust and soot involves a number of steps, including the cooling of charcoal, the purification of dust, the treatment and collection of wood tar oil, and the reuse and recycling of waste.

A charcoal making machine goes through the following four stages during the manufacturing process:

To begin, place the pieces of wood into the wood grinder so that they can be reduced to a finer consistency.

The step that decides whether or not the wood crusher crushing for raw materials and quality will be successful or unsuccessful is one of the most important steps in the process of producing high-quality charcoal. This step determines whether or not the charcoal will be successful. According to the results of a plethora of tests and investigations, the best raw material is one that has been processed through the machine that makes charcoal to a particle size of three millimeters. If the amount of wood that has been crushed is not satisfactory, it is recommended that the process of wood crushing be carried out a further two or three times. The Shuliy mechanical wood grinder, which has a manganese steel alloy and carbon blade, has a performance that is both consistent and high, and it has a high crushing efficiency.